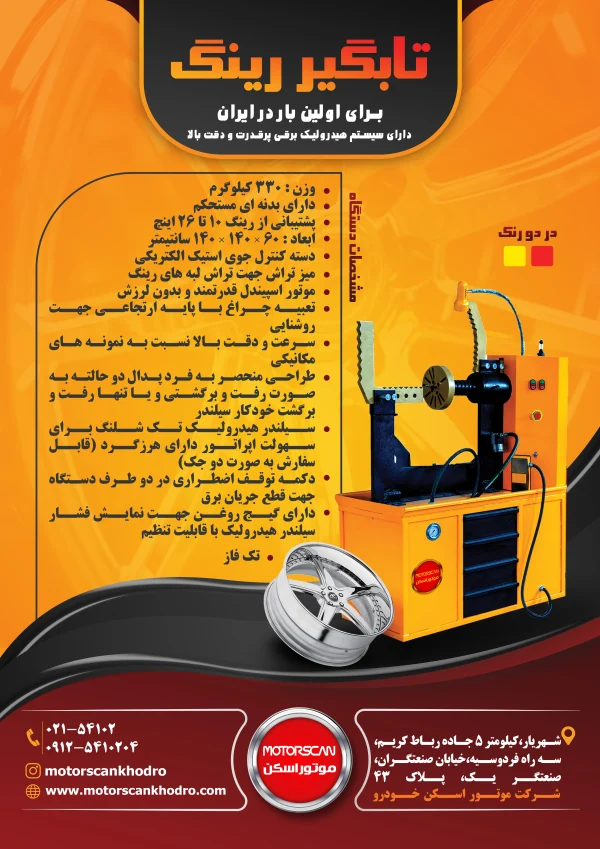

Wheel Rim Straightener

تومان 24,000,000

- Description

- Reviews (0)

Description

Electric Hydraulic Wheel Rim Straightener | Specifications and Purchase Guide

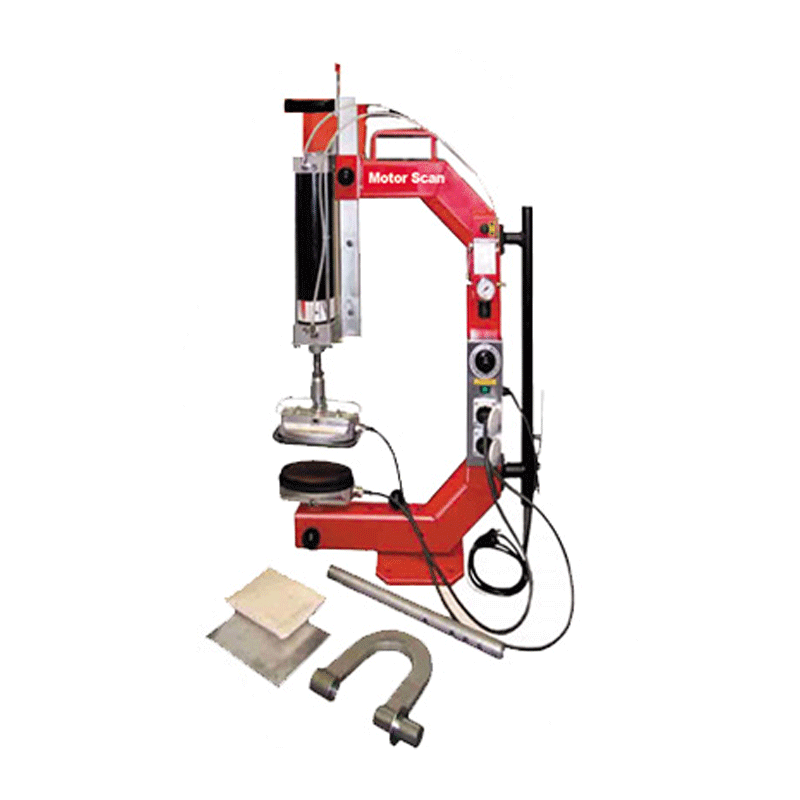

The Electric Hydraulic Wheel Rim Straightener is a specialized and essential piece of equipment for professional automotive workshops and service centers. This device plays a crucial role in repairing and correcting vehicle rims, eliminating bends or deformations in aluminum and steel rims caused by impacts, accidents, or prolonged use. Such deformations can directly affect driving quality and vehicle safety.

In modern professional workshops, the wheel rim straightener is recognized as a vital tool for delivering precise and high-quality services. The device restores the original shape of rims without damaging the metal structure, reducing replacement costs and increasing customer satisfaction. Therefore, selecting a device with advanced technical capabilities and durable construction is essential for automotive technicians and workshop owners.

Electric hydraulic wheel rim straighteners offer significant advantages over traditional mechanical models, making the rim repair process faster, more precise, and safer. Utilizing advanced hydraulic systems and electronic controls, these devices allow precise adjustment of pressure and movement, ensuring optimal rim alignment and straightening.

For any professional workshop aiming to enhance service quality, an electric hydraulic wheel rim straightener is a must-have. It not only improves efficiency but also maintains vehicle safety and mechanical integrity while enhancing customer satisfaction and workshop productivity.

Key Features and Specifications

Robust and Durable Construction

The device features a strong, high-quality body capable of withstanding heavy loads and repetitive use while resisting impact and wear. This ensures long-lasting durability and reduces the need for frequent maintenance.

Advanced Electric Hydraulic System

At the heart of the machine is a sophisticated electric hydraulic system, which provides precise control of cylinder pressure and movement. This system minimizes manual effort, enabling faster, more accurate, and energy-efficient rim straightening.

Powerful Vibration-Free Spindle Motor

The spindle motor minimizes unwanted vibrations, ensuring high precision during the straightening process. It provides reliable performance for extended heavy-duty operations, giving technicians confidence in various working conditions.

Supports Rim Sizes 10–26 Inches

The device accommodates a wide range of rim sizes, from 10 to 26 inches, making it suitable for passenger cars, SUVs, vans, and light commercial vehicles. This flexibility allows workshops to serve a diverse range of customers.

Dimensions and Weight

-

Dimensions: 140 × 140 × 60 cm

-

Weight: 3300 kg

These dimensions reflect the device’s sturdy construction and advanced components, requiring adequate workshop space for safe operation.

Dual-Mode Pedal Design

The dual-mode pedal allows the operator to choose between forward/reverse or automatic cylinder motion, providing flexibility based on the task and technician preference.

Joystick Control Handle

An electric joystick enables smooth and precise control of all movements, ensuring high-quality straightening results with minimal operator effort.

High Speed and Accuracy

Compared to mechanical models, the electric hydraulic rim straightener offers superior speed and precision, reducing repair time while improving the final quality of the rims.

Single-Hose Hydraulic Cylinder

The single-hose hydraulic cylinder simplifies operation while maintaining consistent pressure for accurate and uniform rim straightening.

Oil Gauge and Pressure Adjustment

An integrated oil gauge displays cylinder pressure, allowing technicians to set the exact working pressure for optimal performance and safety.

Flexible Work Light

A built-in adjustable work light ensures proper visibility during operation, reducing errors and improving accuracy.

Rim Edge Trimming Table

The integrated trimming table allows precise correction of damaged rim edges, restoring them for reuse.

Benefits of Electric Hydraulic Wheel Rim Straightener

Enhanced Accuracy and Quality

The electric hydraulic system allows precise adjustment and smooth operation, restoring rims to their original shape while preventing damage. High-quality repairs increase customer satisfaction and reduce the need for repeat services.

Reduced Repair Time and Increased Workshop Efficiency

High-speed operation and ease of use significantly reduce repair time compared to mechanical models, allowing workshops to service more vehicles in less time. Ergonomic controls reduce operator fatigue, further improving productivity.

Improved Safety and Comfort for Technicians

Equipped with emergency stop systems and ergonomic joystick controls, the device ensures safe, low-risk operation. Technicians can work confidently with minimal chance of accidents.

Durability and Long Lifespan

With a sturdy body, high-quality components, and modern hydraulic system, the device minimizes maintenance needs. Long-term after-sales support ensures a secure investment for workshops.

Flexibility in Service

Supporting rim sizes from 10 to 26 inches and offering multiple operation modes, this machine is adaptable for repairing a wide range of vehicles, including passenger cars, SUVs, vans, and light trucks.

Specialized Applications

-

Correcting Aluminum and Steel Rim Bends

Effectively restores bent or warped rims without damaging the metal. -

Suitable for Passenger and Heavy Vehicles

Supports a wide variety of vehicle types, enhancing workshop service capabilities. -

Prepares Rims for Tire Installation

Ensures proper tire mounting, reducing steering vibration, uneven tire wear, and safety risks. -

Repairing Damaged Rim Edges

The integrated trimming table allows precise edge repairs for functional and aesthetic restoration. -

Use in Tire and Rim Service Centers

Enhances efficiency, precision, and safety in professional tire and rim repair facilities.

Summary

The Electric Hydraulic Wheel Rim Straightener is an advanced, professional-grade tool for automotive workshops, enabling high-precision rim repair. Its electric hydraulic system, joystick control, dual-mode pedal, and durable construction allow efficient, accurate, and safe operation.

This device improves repair quality, reduces downtime, and provides ergonomic and safe use for technicians. With long-lasting durability and comprehensive after-sales support, it is a smart investment for professional workshops aiming to enhance service quality and customer satisfaction.

Reviews

There are no reviews yet.