- Description

- Reviews (0)

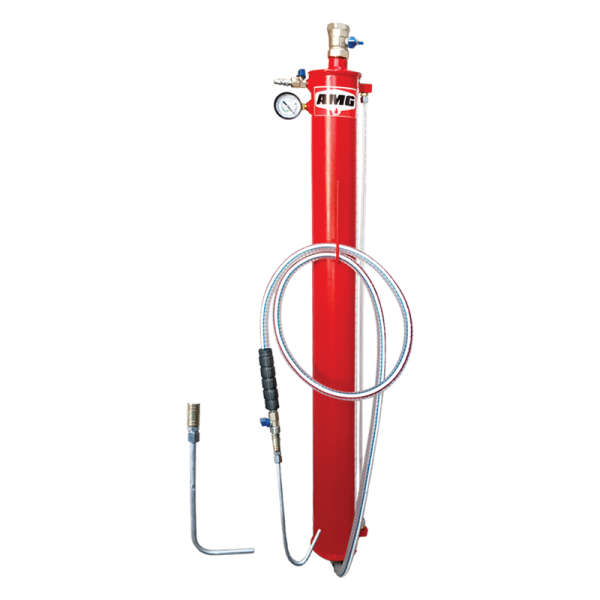

Description

Advantages of the Strong Pneumatic Oil Suction: Speed, Cleanliness, and Safety

Automotive technicians always face challenges when quickly and cleanly draining engine oil. Traditional methods are time-consuming and risky: spilling oil on the floor, direct contact with hot oil, and prolonging the oil change process not only reduce workshop efficiency but also affect the customer experience.

The Strong Pneumatic Oil Suction Machine, with its industrial design and high quality, offers a professional solution to these problems. Using this device, the oil change process becomes faster, cleaner, and safer, allowing your workshop to provide more professional services to customers.

How Does the Pneumatic Oil Suction Work?

When the device is turned on, air inside the glass container above the tank is evacuated, creating a vacuum that draws engine oil through the hose into the container. The process works as follows:

-

Connect the hose from the engine to the tank.

-

The pressure difference between the engine and tank guides the oil into the tank without spilling or direct hand contact.

-

The technician can perform the oil drainage process quickly and safely.

This functionality allows workshops to operate faster and more professionally while reducing risks associated with contact with hot oil.

Benefits of Using the Strong Pneumatic Oil Suction

-

High Speed Oil Changes

With rapid suction, oil changes take less than 5 minutes for light vehicles and SUVs. This speed allows the workshop to increase daily service capacity and serve more customers in less time.

Practical Example: In a workshop using traditional methods, changing the oil of an SUV took about 20 minutes. With the Strong Pneumatic Oil Suction, this time dropped to 5 minutes, allowing the workshop to service two additional vehicles in the same time frame.

-

Cleaner Work Environment

Hot oil no longer spills onto the floor, keeping the workshop clean and safe. This ensures hygiene standards are maintained and customers receive services in a professional environment. -

Greater Safety for Technicians

Reduced contact with hot oil significantly lowers the risk of burns and injuries. Technicians can work faster and with less stress, increasing productivity and reducing workplace accidents. -

Compatible with All Vehicle Types

The device can be used for light, medium-duty, and some industrial vehicles, making it versatile and eliminating the need for multiple machines.

Professional Tips for Maximum Workshop Efficiency

-

Choose the Right Device: Select the tank capacity and hose length according to your workshop needs and vehicle types to optimize performance.

-

Regular Maintenance: Cleaning and servicing the tank, hoses, and connections increase the device’s lifespan.

-

Staff Training: All employees should know how to operate, maintain, and safely use the machine to ensure a fast and trouble-free process.

-

Air Pressure Control: Set the compressor pressure to 6 bar for maximum efficiency.

-

Use Appropriate Tubing: For heavier vehicles and SUVs, use longer hoses to ensure complete suction.

Pro Tip: Workshops following these guidelines achieve shorter service times and higher customer satisfaction.

Frequently Asked Questions

Is this device suitable for all vehicles?

✅ Yes, with the appropriate hose, it can be used for light, medium-duty, and industrial vehicles.

What should the compressor air pressure be?

✅ Around 8 bar is recommended for optimal oil suction.

Is maintenance difficult?

✅ No, regular cleaning of the tank and periodic service make maintenance simple and low-cost.

How long does the device last?

✅ With proper maintenance, the device operates flawlessly for years.

Does it require electricity?

✅ No, it runs entirely on compressor air pressure, with no direct electrical connection needed.

Reviews

There are no reviews yet.